Soft Story Solutions

The structural expertise you can rely on to efficiently improve seismic resilience and ensure compliance. Bold Steel is expert in designing retrofit options. We combine our understanding of our client’s business with our structural engineering experience to arrive at retrofit solutions. Some of the common methods employed to retrofit soft-stories include the installation of:

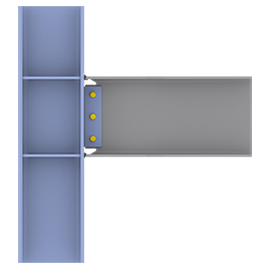

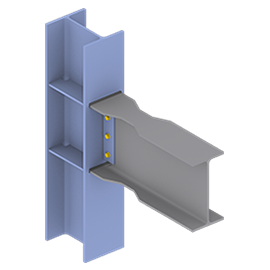

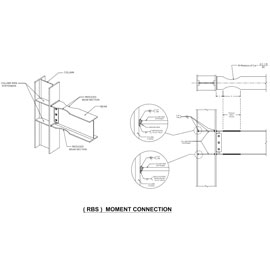

1) Reduced Beam Section (RBS) moment connections.

In Reduced Beam Section (RBS) moment connections, portions of the beam flange are selectively trimmed in the region adjacent to the column-beam connection to ensure yielding and hinge formation within the reduced area. This connection type can be used for special Moment Frame (SMF) and Intermediate Moment Frame (IMF) systems.

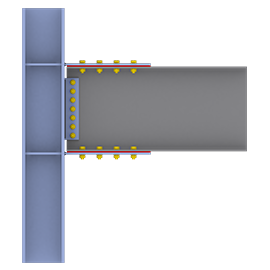

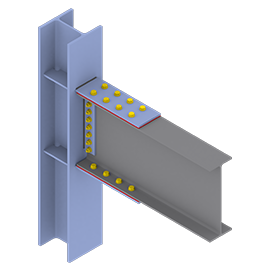

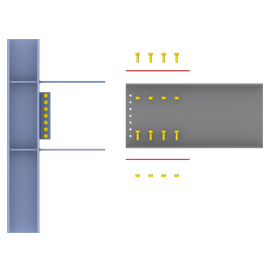

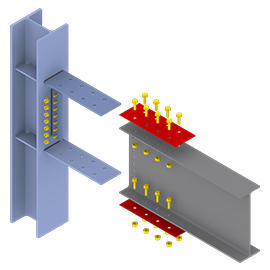

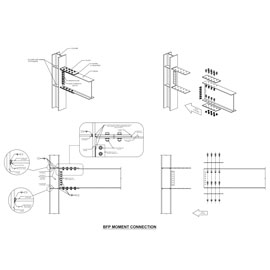

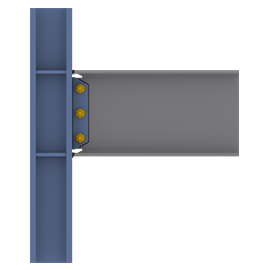

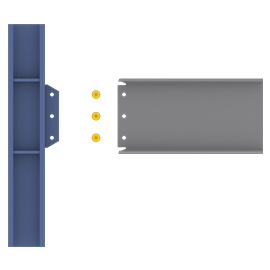

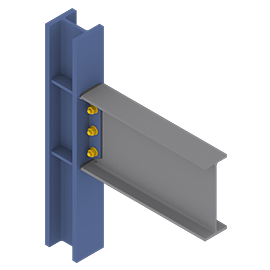

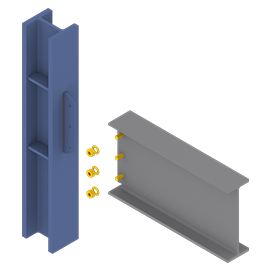

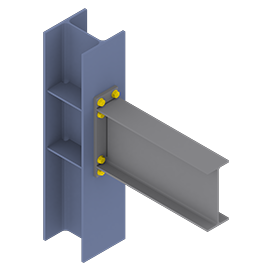

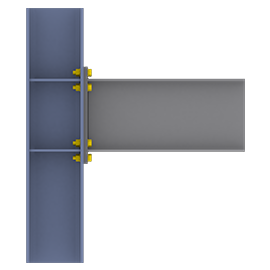

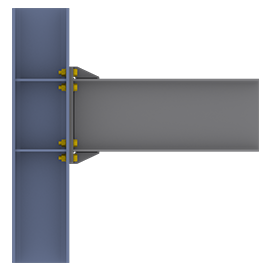

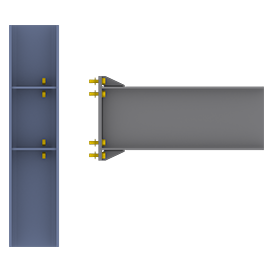

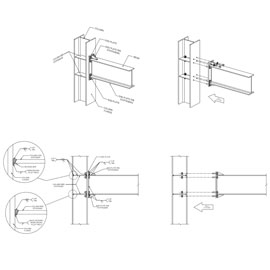

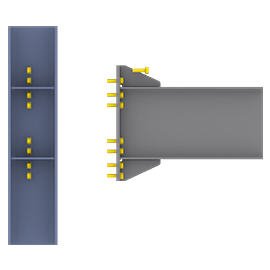

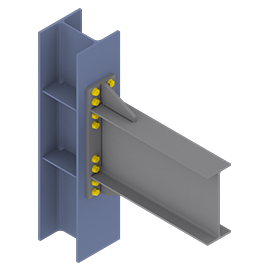

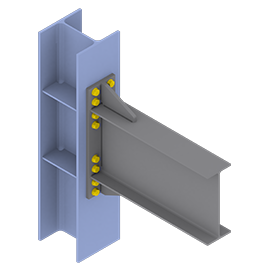

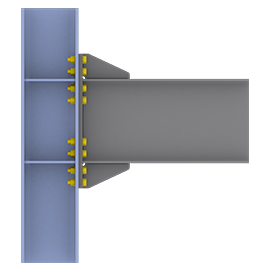

2) Bolted Flange Plate (BFP) moment connections.

Bolted flange plate (BFP) moment connections use plates welded to column flanges with complete-joint-penetration (CJP) groove welds and bolted to beam flanges with high-strength bolts. The beam web is connected to the column flange using a bolted single-plate shear connection with bolts in short-slotted holes. Inelastic rotation is intended to occur in the beam in the region near the end of the flange plates.

The flange plates and web shear plate are shop welded to the column flange and field bolted to the beam flanges and web, respectively. ASTM A490 or A490M bolts with threads excluded from the shear plane are used for the beam flange connections because the higher shear strength of the A490 or A490M bolts reduces the number of bolts required and reduces the length of the flange plate.

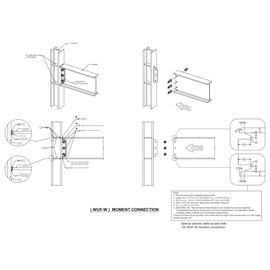

3) Welded Unreinforced Flange Welded Web (WUF-W) moment connections.

Welded unreinforced flange welded web (WUF-W) moment connections utilize CJP+ Groove welds to connect the beam flanges to the column flanges. The beam web is bolted to a single-plate shear connection for erection. Subsequently, this plate is used as a backing bar for a CJP groove weld between the beam web and the column flange. A fillet weld also is used as shown in figure below. Inelastic rotation is intended to occur in the beam in the region adjacent to the face of the column.

The welded unreinforced flange-welded web (WUF-W) moment connection is an all-welded moment connection, wherein the beam flanges and the beam web are welded directly to the column flange.

Welds used for this connection need to meet the requirements of demand critical tabs and welding quality control and quality assurance requirements.

The WUF-W moment connection employs a special seismic weld access hole with requirements on size, shape, and finish that reduce stress concentrations in the region around the access hole, (see figure below for access hole).

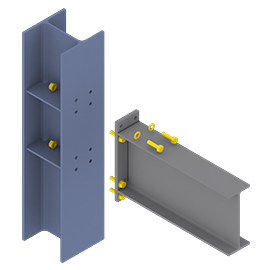

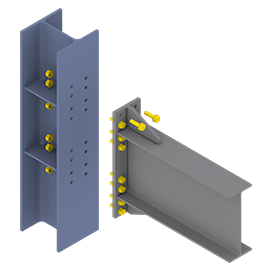

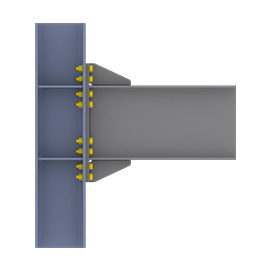

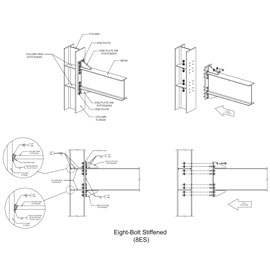

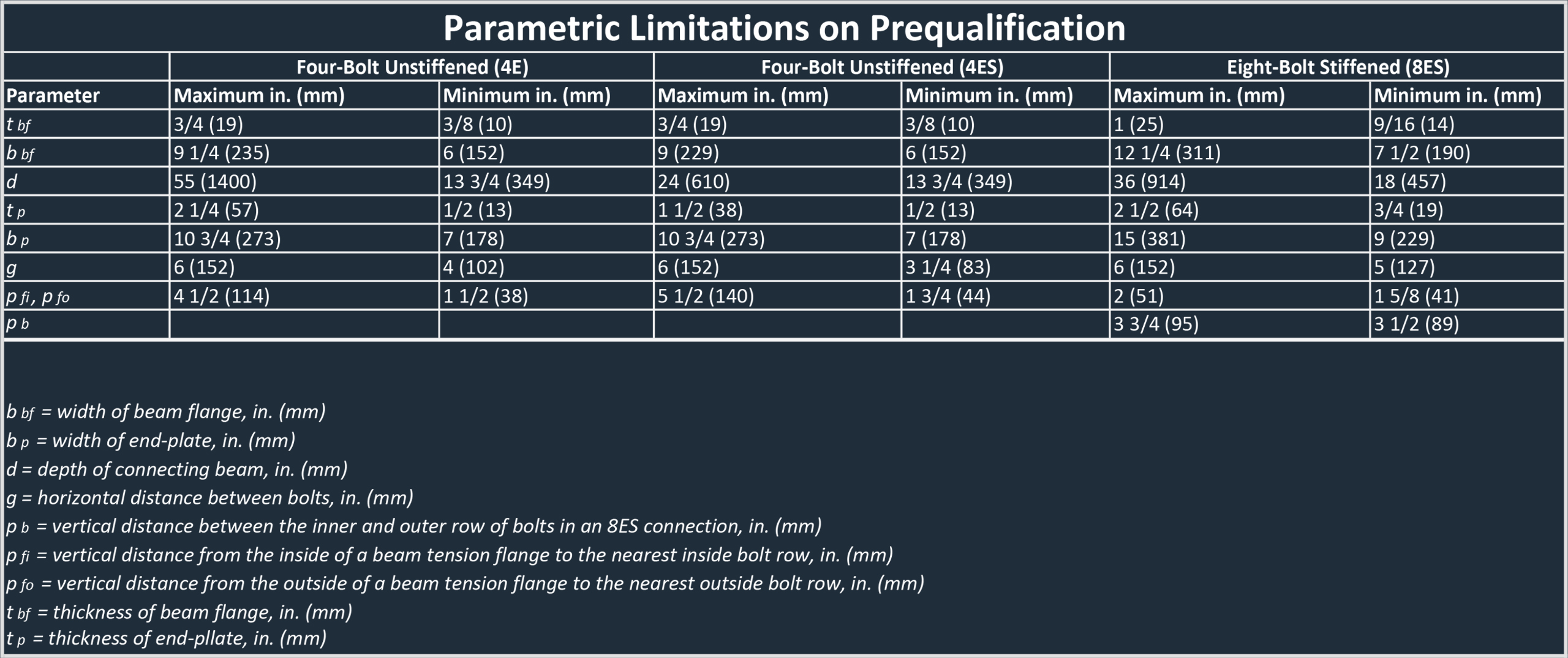

4) Bolted Unstiffiened Extended End-Plate (BUEEP) & Bolted Stiffened Extended Ent-Plate (BSEEP) moment connections

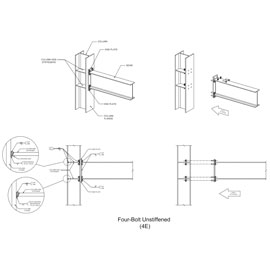

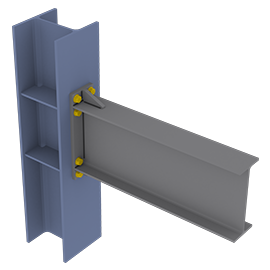

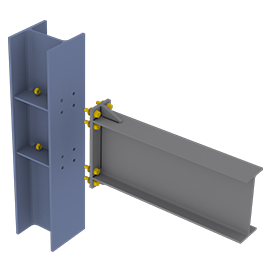

Bolted end-plate connections are made by welding the beam to an end-plate and bolting the end-plate to a column flange. Extended end-plate moment connections are prequalified for use in special moment frame (SMF) and intermediate moment frame (IMF) systems.

Exception:

Extended end-plate moment connections in SMF systems with concrete structural slabs are prequalified only if:

1. In addition to the limitations of Section 6.3, the nominal beam depth is not less than 24 in. (610 mm); 2. There are no shear connectors within 1.5 times the beam depth from the face of the connected column flange; 3. The concrete structural slab is kept at least 1 in. (25 mm) from both sides of both column flanges. It is permitted to place compressible material in the gap between the column flanges and the concrete structural slab.

Following three end-plate configurations are prequalified under the AISC seismic provisions within the limitations of this standard.

4 Bolt Unstiffened (4E) – Connection:

4 Bolt Stiffened (4ES) – Connection:

8 Bolt Stiffened (8ES) – Connection:

Cantilevered Column Systems is a seismic force-resisting system in which lateral forces are resisted entirely by columns acting as cantilevers from the base.

The required axial strength of individual cantilever column elements, considering only the load combinations that include seismic load effects, shall not exceed 15 percent of the available axial strength, including slenderness effects. Foundation and other elements used to provide overturning resistance at the base of cantilever column elements shall be designed to resist the seismic load effects including over strength factor of Design.